Ghodbunder Road, Thane, Maharashtra

- GST NO. : 27AHYPC3352L1ZV

Ultrasonic Btu Meter

Leading Manufacturers, Exporters, Wholesaler, Retailer and Trader of Clamp On Ultrasonic Btu Meter, 15mm to 40mm Inline Ultrasonic Btu Meter and 50mm to 350mm Inline Ultrasonic Btu Meter from Thane.

| Business Type | Manufacturer, Exporter, Supplier |

| Make | CBRO |

| Model | CUF250C Series |

| Measuring Principle | Transit time difference |

| Mounting | wall mounting, panel, local |

| Transducer type | clamp-on, spool piece, or insertion |

| Display | LCD with backlight, 2 x 20 characters 1-line, non-backlit 7 digit LCD (ILD version) Displays energy rate, total consumption, temperature, instantaneous flow rate, accumulated flow rate, velocity, time |

| Keypad | 4 x 4 tactile-feedback membrane keypad |

| Pipe Size | 25-6000mm |

| Pipe Material | Carbon Steel, Stainless Steel, Ductile Iron Copper, PVC, Aluminum, Asbestos Fiberglass, etc. |

| Output Signals | 4-20mA , Impedance 0-1kΩ, pulse, relays, Isolated OCT for alarms (on/off with buzzer) |

| Inputs | Two RTD channels, and additional inputs |

| Product Code | UFC250W |

| Port | Mumbai |

| Payment Terms | T/T |

| Delivery Time | 2-3 Days |

Preferred Buyer From

| Location | Worldwide |

The clamp-on ultrasonic heat meter is combined by our high accuracy clamp-on ultrasonic flow meter together with standard platinum temperature sensors (PT100 or PT1000),then get result of thermal energy measurement transferred from flow measurement in a closed pipe accordingly.

The ultrasonic heat meter system mainly includes three parts: the main unit, the ultrasonic clamp-on type transducers, and the temperature sensors(PT100 or PT1000). The main unit is a high-accuracy ultrasonic transit-time flowmeter. Its enclosure can be a standard version or an explosive-proof version. The ultrasonic transducers are clamp-on type and very easy to install. The temperature sensors can be standard Pt sensor or customer-supplied sensor.

The calorimeter can be used for energy consumption measurement of a heating / cooling system in office buildings, apartment complexes, or any liquid-based thermal energy production system. It can also be used to monitor the efficiency of an energy production system such as HVAC installation.

Key Features:

- Horizontal or vertical Installation

- Transducer Max Temp: -20C to +160C

- Accuracy: +/-1% of reading above 0.6ft/sec / 0.2 m/sec

- Outputs available: 1x 4-20mA , 1x Pulse Output , 1x Alarm Output (All configurable)

- ModBus output

- Ingress Protection: Display= IP65, Transducers= IP65 (IP68 on request)

These ultrasonic flow meters can be used on virtually any pipe size or material, are non-invasive and are therefore not prone to the levels of deterioration that are seen by traditional intrusive flow meters. Mbus converter, Radio Pulse transmission and GSM/GPRS Telemetry / logging options on request.

Features:

- High accuracy - ±1% of reading

- Bi-directional flow measurement

- Wide range of fluid velocities - 0.03 ~ ± 105 feet/sec.

- Transducers for pipe sizes ranging from ½" to 240" (15 to 6000 mm)

- Measures energy consumption rate and total

- No moving parts,

- Fixed and Portable version

- Proven ultrasonic technology for flow measurement and PT 100 for temperature

- Clamp-on, spool piece or insertion mounting for flow measurement

- RS485 and Modbus communication protocols available

- 4-20mA and pulse outputs with available relays and alarms

- Data logger function - includes time & date, totalizer, diagnostics

- Fast response time - less than 1 second

- NIST traceable calibration certificate (optional

Applications:

- BTU metering system

- HVAC/Energy Monitoring

- Building Automation / HVAC

- Energy consumption supervision and water conservation management

- Cooling system and air conditioning/glycol solutions

- Heating & District Heating Solutions & Systems

- Smart Heat meteing

- Thermal energy measurement (heating and conditioning) and water metering (cold and worm)

| Business Type | Manufacturer, Exporter, Supplier |

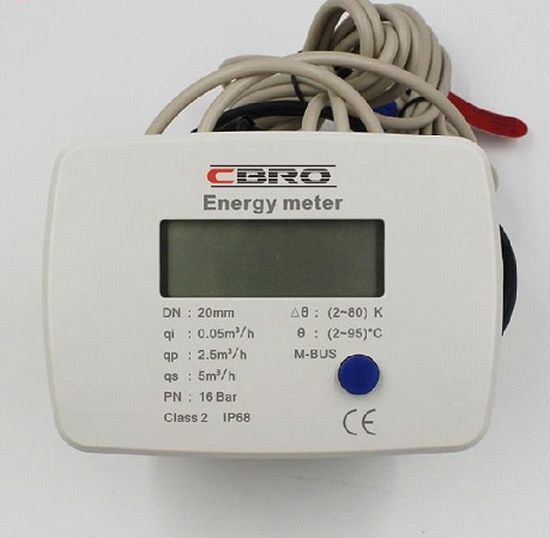

| Make | CBRO |

| Model | UBM250I-T |

| Measuring Principle | Transit time difference |

| Mounting | wall mounting, panel, local |

| Transducer type | clamp-on, spool piece, or insertion |

| Display | LCD with backlight, 2 x 20 characters 1-line, non-backlit 7 digit LCD (ILD version) Displays energy |

Preferred Buyer From

| Location | Worldwide |

The threaded ultrasonic BTU meter UBM250I-T is designed for measuring thermal energy of small area where pipe size is not bigger than 40mm , e.g. apartment, villa, shop, etc. The BTU meter comprises of ultrasonic flow sensor and two temperature sensors, base on flow rate and differential temperature of supply / return water to calculate the thermal energy consumption. The product adopts a design of straight-through pipe, features with high measurement accuracy, low pressure drop, anti-blocking, stable operation and long service life. The product can be widely used in central heating/cooling and district heating/cooling systems for thermal energy measurement of residential, commercial and office building.

- High-quality fully enclosed ultrasonic element ensure accuracy and stability of flow measurement

- Using high-quality PT1000 temperature sensors, calibrated and matched to an accuracy better than +/- 0.1 ° C.

- Casing protection class IP68.

- Can be installed horizontally or vertically, and the head is detachable.

- With M-bus / Modbus protocol interface, compatible with BMS for remote reading function. RS485 is optional.

- Detachable battery case for quick replacement.

- Can be mounted on supply or return pipe (specify when ordering);

- Can be used for both heating and chilled water.

| Business Type | Manufacturer, Exporter, Supplier |

| Make | CBRO |

| Model | UBM250I-F |

| Measuring Principle | Transit time difference |

| Mounting | wall mounting, panel, local |

| Transducer type | clamp-on, spool piece, or insertion |

| Display | LCD with backlight, 2 x 20 characters 1-line, non-backlit 7 digit LCD (ILD version) Displays energy |

| Product Code | BTU250 Series |

| Port | Mumbai |

| Payment Terms | T/T |

| Delivery Time | 4-5 Days |

Preferred Buyer From

| Location | Worldwide |

The BTU meter comprises of an ultrasonic flow sensor and two temperature sensors, base on flow rate and differential temperature of supply / return water to calculate the thermal energy consumption. The flow sensor uses ultrasonic flow measuring technology which measures accurately, and not affected by iron rust contained in the flow and external magnetic field. The meter body is made of cast iron, fabricated by hard mould forging, CNC machines, features with good mechanical strength and high accuracy of dimension. Long-term life cycle, stability and accurate operation of the BTU meters are guaranteed. The temperature sensors use PT1000 platinum resistance matched temperature sensing elements to achieve high-accurate temperature measurement in conjunction with a high-accurate AD circuit. The MCU (Microprogrammed Control Unit) selects the MSP430 series ultra-low power microprocessor from American Tl Company, features with strong functions, low power consumption and strong antielectromagnetic interference capability. With self-diagnosis, fault display and power-loss data memory function, the ultrasonic BTU meter will display error code and store current data automatically in case of sudden failure.

The BTU meter is equipped with LCD screen, showing data completely and accurately in convenient and fast way. Real-time built-in clock is used for date recording and display. The BTU meter features with splittable structure (calculator can be removed from meter body and fixed in other location if necessary), protection class IP68, convenient reading, and single button operation.

- Reliable for various working environment by: metal body, water proof calculator, shielded signal cable prevent from biting of rats.

- High-quality fully enclosed ultrasonic element ensure the accuracy and stability of flow measurement.

- Measuring and displaying thermal energy consumption.

- Displaying water supply/return temperature.

- Displaying differential temperature of supply and return water.

- Displaying current flow rate.

- No mechanical moving parts, free from possible impact of poor water quality, low maintenance costs.

- Low minimum measurable flow rate.

- M-BUS / Modbus interface for remote reading function. RS485 optional.

- Automatic error diagnosis function to ensure safe and accurate operation.

- Can be mounted on supply pipe or return pipe, (specify when ordering).